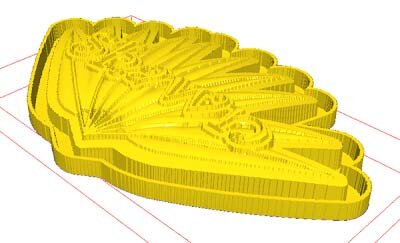

We used a wrench out of our tool box as reference when we created the vectors for Phil’s name plaque. They were done in three sections since each section needed to be different heights and shapes.

We created the reliefs individually and merged them together before going to the next step.

The raised name plate was created as a separate relief and Phil's name was embossed using the subtract from relief tool - all in EnRoute.

After this, we used the subtract from relief tool once more (in the dome mode) to create the beveled dimple in the box end of the relief.

Then we created a zero height relief of the eight sided box end. This was merged with the wrench using merge lowest function.

As simple as that, the wrench file was finished and ready to tool path.

A piece like this makes a nice display piece and would make a great gift for anyone who likes to tinker in their workshop.