Each year we do a variety of projects. All are special. And we do our very best to make them all outstanding. Last year was no exception. Inevitably one project stands out because it is so different than anything else out there. The project that qualifies this year is one we are really proud of. I’ve shown bits and pieces of it on the blog while it was in progress, but never a complete set of the finished project. I thought I would do that here today.

The project was for MultiCam Western Canada. They are a dealer and service center for MultiCam CNC equipment and software. They offer a variety of machines including CNC routers, plasma cutters, water jets, and lasers. The company is located in Langley, British Columbia, Canada. The owner is Sean Lawlor. Sean had sold us a MultiCam CNC router five years ago, which we have been very happy with every since. When Sean visited my office the first time he loved what he saw. He also promised me that some day when he expanded his business we would get the call to decorate his office. Last year we got the call.

My mandate was simple. I was to create a ‘Disneyland’ for CNC machines. Each element of the design we created was designed to show the capabilities of the machines they sold. While the bulk of the project would be done in our shop, on our own MultiCam CNC router, Sean also promised I could play with his new equipment on the showroom floor. This would prove to be more fun than I could possibly imagine. And while Sean did have a generous but firm budget in mind, there were no other limits. I could do as I pleased. Sean placed his trust completely in me.

The outside of the building looks like any other in the complex. Regulated by the strict strata laws and the City of Langley the signs are pretty typical - and done by someone else. Inside it is a completely different story. In the lobby we opted for a robotic theme. CNC machines are robots after all. The desk is massive, with huge robotic arms reaching over. They are in fact lamps. The MultiCam logo is embossed boldly into the front, and on the arms the soon to be familiar ‘M’s appears no less than sixteen times. Sean’s name is hidden in the hydraulic cylinders which assist the heavy mechanical machines. The stair railing, signs, and even the wainscoting all showcase the work of a MultiCam CNC router and subtly (sometimes not so subtly) remind guests they are at the MultiCam facility. This was but the tip of the proverbial ice burg. Lots more was in store for those who were invited past this point.

The hallways and common areas feature more subtle branding through the wainscoting, corner blocks on the doors and windows and in the way finding signs. But as you go down the hallway one sign looks different than the rest. A starfish clings to the board room sign giving a small hint as to what might lurk inside. The door to the board room sports two aged and weathered portholes. The windows are glazed with grime. This is no ordinary board room.

As the double doors swing open every visitor is instantly transported to another world under the sea. The walls glow with an otherworldly blue glow. A model submarine decorates the far wall. Massive, rusted steel beams support the curved ceiling overhead, all lights focused on the large board room table which dominates the room. On one end of the room a heavy copper door hides the white board. The requisite pens are held in a pen holder like none other ever imagined. The other end of the room features a LED TV in full theme of course. Gauges and dials give it an unknown and mysterious function. Everything is branded with the MultiCam logo but without breaking the clever storyline. The table has a large hole cut into the center, with a glass insert. Computer hookups connect each participant to the company network. This room will also double as a training center.

We had great fun as we added idea after idea to the room. It is actually built from materials other than what appear. We have discovered a paint that forms real rust when we treat it with a special solution. The aging on the other parts was done with layer after layer of patina - all carefully applied by hand.

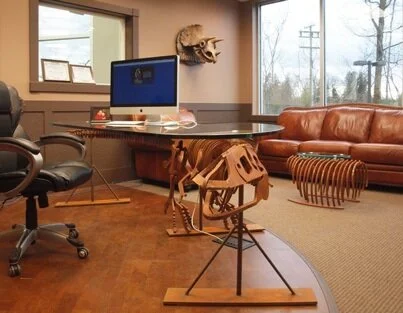

Upstairs we got to play in one more office in a big way. Sean’s office would be the ‘Jurassic Room’. Here we would showcase the MultiCam pCNC plasma cutter. I created the file and then it was time to have some sun with a factory fresh machine. We loaded a 1/2” thick plate of steel onto the bed with a big forklift, then set the machine in motion. Amazingly in mere minutes it had perfectly cut more than 300 bone shaped pieces for the desk and coffee table. I took them back to my shop and welded them together according to the plan.

The desk was sprayed with a mild acid to produce an instant rust patina. Other dinosaur or fossil themed pieces were also designed and crafted for the room - all demonstrating the capabilities of the wondrous CNC machines.

The end result of our efforts is a truly memorable office and showcase for the company. Each potential customer does not have to ask what the machines are capable of - it is amply demonstrated for them at every turn. It is instantly obvious to all that if the machines can do all the things they see. they are also capable of doing what they need them to do. Sean is delighted with the result. He says the decor we built into his office gives them instant credibility.

We are excited with the result as it is already opening up new opportunity for us too. Each client we have taken through the facility wants us to work that same magic for them. Imagine where we can go from here...

-grampa dan